Polymer professor develops safer component for lithium batteries

The power source for implanted medical devices, electric cars, unmanned aerial vehicles and other such objects is vital to their performance. So, what would happen if that powerhouse of energy — a lithium battery — failed? An electric or hybrid car would be rendered useless and a much-needed biomedical device would hamper a patient’s health.

These are the types of outcomes Dr. Yu Zhu, a professor of polymer science, along with other researchers, is trying to prevent.

A recent paper from Zhu’s research group, “A Superionic Conductive, Electrochemically Stable Dual-Salt Polymer Electrolyte,” will be published Tuesday in Joule, Cell Press’s forward-looking journal spanning energy research across disciplines.

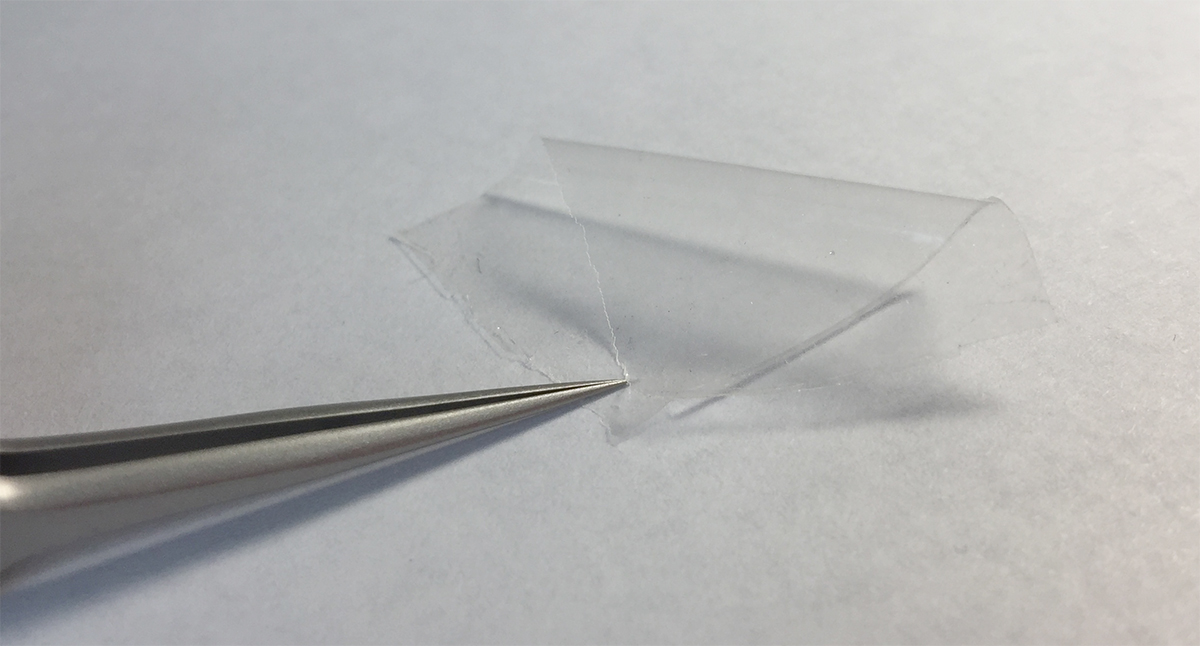

Specifically, Zhu and his research team developed a solid polymer electrolyte that can be used in lithium ion batteries to replace the current liquid electrolyte to improve the safety and performance of lithium batteries.

Dr. Yu Zhu

Zhu says solid electrolytes have not been commercialized in lithium batteries because of drawbacks like low ionic conductivity and high interfacial resistance with electrodes. However, Zhu and his team demonstrated that a dual-salt based polymer solid electrolyte exhibited superionic conductivity at room temperature and outstanding electrochemical stability with lithium battery electrode materials.

“A solid electrolyte has long been thought for lithium ion batteries due to its nonflammable property and high mechanical strength that may mitigate the disaster caused by battery failure,” says Zhu. “Battery safety and energy density are major concerns for emerging applications of lithium batteries, such as for use in electrical vehicles. If the solid polymer electrolyte is successfully developed, the energy density of the battery could be doubled and the safety concerns for lithium batteries could be removed. This research sets up a strong base to develop such a promising solid electrolyte for lithium batteries.”

The research team has formed a company, Akron PolyEnergy Inc., that will further develop this technique and produce a large prototype for future commercialization.

Zhu’s graduate students, Si Li and Yu-Ming Chen, are leading authors for this research. Other researchers include graduate students Wenfeng Liang, Yunfan Shao and Kewei Liu, and Dr. Zhorro Nikolov, instrumentation scientist at the National Polymer Innovation Center on campus.

Media contact: Alex Knisely, 330-972-6477 or aknisely@uakron.edu.